any products - any design - any compliance - any industry

small - medium - high quantities

Metal forging and Steel forging

MiMfactories provides custom steel forgings manufactured to meet your exact design requirements. We produce high quality, high precision steel forgings for numerous industries, from construction to automotive and everything in between.

Depending on the demands of your part designs, products can be hot forged or cold headed. Hot forging is ideal for larger parts and applications where optimum yield strength, high ductility, and a better surface quality are preferred.

Cold heading is better suited to producing smaller parts and components, and the process automatically work-hardens the material, resulting in high strength products.

| OEM high quality steel Forging | |

| Application | vehicle,mining,agriculture and construction machinery |

| Standards available | ISO,EN, DIN,GB, JIS, AISI, SAE, ASTM/ASME |

| Material | carbon steel, alloy steel, stainless steel |

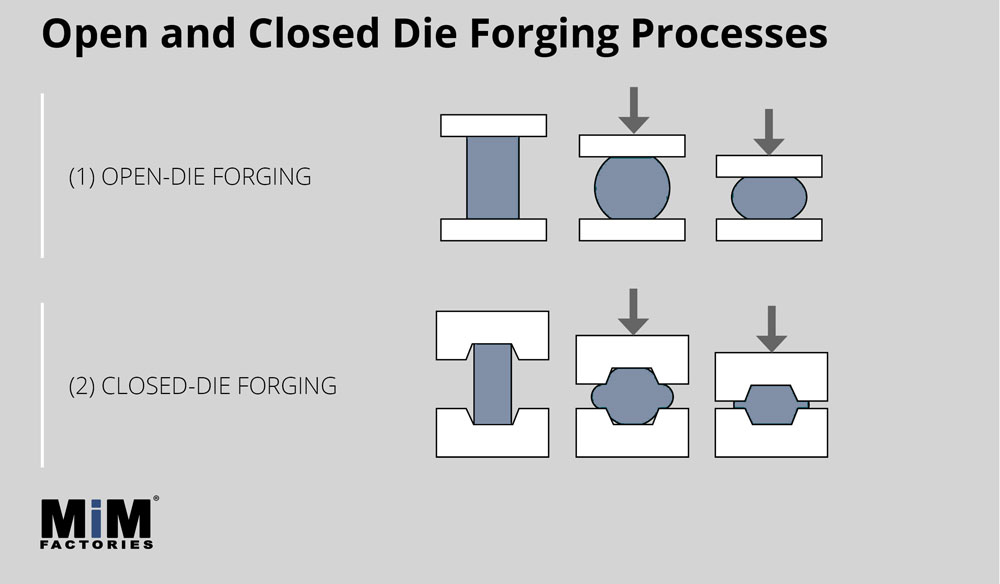

| Production process | drop forging ,machining |

| General tolerances

on dimensions |

EN 10243-1-grade F for forging

ISO 2768-mK for machining |

| Size | up to 200kg custom |

| Acceptable data formats | DWG,DXF,IGES,STEP,XT |

Hot Forging & Cold Heading

We provide both hot forging and cold heading to meet the forging needs of nearly any industry or application. As needed, we will work with you to determine the best forging method for your unique project.

Hot forging is the preferred method for creating parts and components for more rugged applications, such as construction and automotivemanufacturing. The hot forging process improves the yield strength, ductility, and toughness of the material, making for more durable parts. Our forging sources can hot forge a wide range of metals and alloys.

Cold heading is ideal for producing smaller, more intricate parts and components, like those found in medical devices or electronics. Cold heading utilizes high speed, automated equipment to create perfectly repeatable, high precision parts. We can cold head forge numerous metals and specialty alloys.

Hot Forging & Cold Heading

Forged parts exhibit very high strength. The high pressure required to forge steel parts compresses the material and gives it a very dense and refined grain structure that conforms to the part’s shape. This increases the steel’s tensile strength and improves its resistance to impact and abrasion.

Forging also allows for adherence to very close tolerances. The dies used in the forging process result in precise part dimensions with minimal part to part variation. Our factories utilize forging dies that are custom-made to match customer specifications.

Because they are free of internal voids, gas pockets, and cooling defects that can cause undue fatigue or impact load failure, custom forged steel parts are ideal for high load, high stress applications.

Forging Materials

Our specialists are capable of producing durable, high strength forgings from an array of mid-range carbon steel materials. Medium carbon steel provides excellent ductility and strength, and is known for its long-wearing properties. This material is popular for bolts, shafts, car axles, rails, and other parts and components that require high strength and a certain degree of flexibility.

Available steel grades include, but are not limited to:

- 1035

- 1038

- 1040

- 1045

- 1050

- 1117

A number of other grades are available upon request.

Forging Materials

MiMfactories forging sources use the highest quality steel materials available, and utilize state-of-the-art equipment to ensure superior precision and repeatability. We can deliver your forged products in fast turnaround times that fit your schedule and at prices that fit your budget.

In addition to steel forging, MiMfactories also offers services for precision machining and other secondary operations to give you more complete parts and components.

Contact us to learn more about the MiMsactories advantage for the metal extrusion industry.

Small - medium - high order quantity

Product materials of cast iron, cast steel, super duplex, SST, copper based & aluminum based alloys.

- CNC milling (Aluminum, brass, steel, zinc alloy, many others )

- Sheet metal (Steel, Aluminum, many others)

- Die Casting (ADC12,etc);

- Finish :remove bur, sandblast, anodized, painting, printing, plating, high polish, mirror polish, blackening, powder coating, etc.

Here below please find some pictures we have made recently:

FOR FAST QUOTE EMAIL US: 2D/3D DRAWINGS

See examples of our Metal Injection Molding MIM work

Metal Injection Molding services:

Other services

Manufactured Products

- Metal Injection Molding

- Plastics Injection Molding

- Wi-Fi, LAN, Broadband Equipment

- Load Cells and Torque Sensors

- Electronic Components

- Cable Assemblies

- Power cords and Cord sets

- Electronics

- Medical Products

- Computer Products

- Security Products

- Telecom Products

- Machinery Products

- Auto Parts and Accessories

- Hardware & Tools

- Home Products

- Sport equipments

- Baby Products

- Fashion Accessories

- Garments & Textiles

- Power and Electronic Products

- Power Supplies

- Replicas / Miniature Manufacturing

- Packaging design and development

- Toroidal transformer

- Control transformer

- Low frequency transformer

- Audio transformer

- Three phase transformer